Development of instrumentation control, automation and robotics, system integration, SDK, algorithms for signal and image processing and analysis, algorithm optimization, GUI, software installers.

- SDK development for imaging devices (photoacoustics and thermoacoustics, cameras, ultrasound, X-ray detectors).

- Development of control libraries for interfacing with integrated circuits (IC) in a Programmable Logic Controller (PLC) or Graphical User Interfaces (GUI) environment.

- Serial & network communication through a variety of protocols (including I2C, SPI, UART, and TCP/IP) for the purpose of original equipment manufacturer (OEM) device integration.

- Integration of robotics and automation into imaging systems.

- Development of algorithms for signal and image processing and analysis (C++, C#, Python, MATLAB, LabVIEW).

- Optimization of computer vision and image processing algorithms on CPU (x86_64, aarch64) and GPU (CUDA).

- Writing bindings for libraries for Python, C# languages.

- Design of multi-language interfaces for supporting diverse end-user needs.

- Cross-platform GUI development in C++/Qt or C#/WPF (Windows Only).

- Generation of package installers for simplified software distribution through single-file self-extracting executables (SEE).

Examples of PhotoSound software development solutions

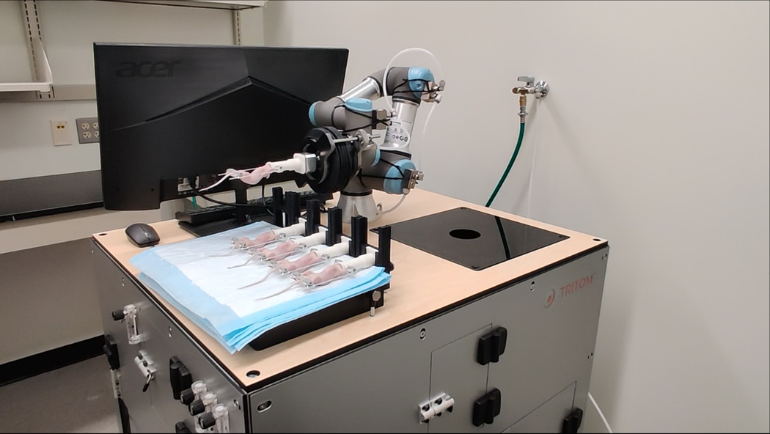

- High-Throughput TriTom imaging system (TriTom HT) – utilizes a Universal Robots UR3e 6-degree-of-freedom robotic arm and the GUI developed for this system uses TCP/IP communication to manage calibration and path adjustment, automated scan procedures in coordination with other imaging hardware, real-time indicators of robot arm positions in tool coordinate and joint coordinate systems, etc.

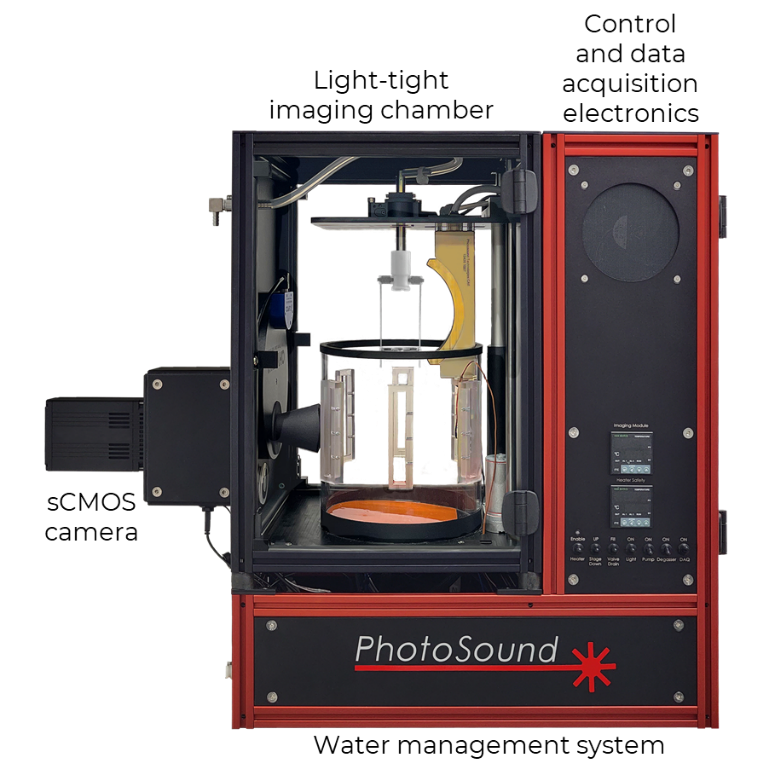

- TriTom Premium Imager and TriTom Acquisition Suite – data acquisition software suite for a multimodality (photoacoustics and fluorescence) imaging platform. Multiple instruments are integrated (photoacoustic data acquisition, camera, filter wheel, laser, rotary scanning device, etc.).

- TriTom Imaging Suite – manages TriTom data, reconstruction, processing, and analysis of 2D and 3D images and molecular maps. Straight-forward, intuitive data processing workflow that includes selection of data sets, focusing of images, 3D reconstruction, unmixing of molecular maps, and basic analysis of the images (ROI selection and statistics).

- MoleculUS Imager and MoleculUS Imaging Suite – a comprehensive data acquisition and real-time imaging software suite for another multimodality (ultrasound and photoacoustics) imaging platform.

- Acceleration/optimization of TriTom 3D photoacoustic tomography – filtered back-projection algorithm for a rotationally symmetric data acquisition geometry. The processing was accelerated by ≈ 18.5x through CUDA programming. Further optimizing the code into CUDA lead to a 2x acceleration. The reconstruction is 37x faster than prior to CUDA code integration.

- Developed control libraries for Linear Technology LTC® 2983 temperature measurement system and ON Semiconductor® NCV7726B half-bridge driver for general purpose use in higher level programs.

- .NET-based dynamically-linked libraries (.dll) from established MATLAB scripts for use in .NET applications, creating C-style interface (CSI) wrappers to provide a simplified compatibility layer, and building working examples for utilizing PhotoSound SDK C# & C++ libraries through MATLAB scripts or LabVIEW VIs and SubVIs.

Data acquisition solutions, systems and components. From design to small-scale production

- Xilinx FPGA development, production and IPs for existing and custom boards, including Generation 7, Artix-Ultrascale+ and incoming Spartan-Ultrascale+ with 16/3 GB/s GTs and PCIe Gen4.

- FPGA firmware.

- Windows or/and Linux drivers, SDKs and basic application examples in C++, C#, MATLAB, LabVIEW.

- PCIe for Windows and Linux based on free Xilinx IPs only. Artix-Ultrascale+ XCAU15P-2FFVB676E board has speed 5.7 GB/s out of 7.877 GB/s theoretical maximum for PCIe Gen4 x4 (test PC with Ryzen 5-3600) and 2.9 GB/s in Gen3 mode out of 4 GB/s (test PC with i7-8700K).

- USB2 and USB3 based on Cypress FX2 / FX3. 3 Gb/s sustained for USB3 on Windows PC.

- SFP optical transceivers with speed up to GT Xilinx limits.

- DDR4 in laptop SODIMM formfactor.

- High speed ADCs, AFEs and DACs with JESD and LVDS interfaces.

- Skyworks SI5xxx clocks.

- OEM versions of PhotoSound Legion ADCs for enclosure integration.

- Analog design

- Sensor interfaces, transimpedance preamplifiers, amplifiers, noise modeling.

- Compact multichannel design.

- Implementation of multichannel sensor interfaces and preamplifiers in custom IC (ASIC) format with digital control.

- Preamplifier for probe integration for thermoacoustics and other applications.

- Custom multichannel preamplifier for thermoacoustics (for example 40 dB to 50 Ω load over 35 MHz bandwidth, 3.3 V 10 mA/ch single-rail power), with an options of bypass switches for positioning between the pulser (like TI TX7xxx, TX7516) and AFE.

- Design, programming and production of custom sensor and power distribution systems for standalone use and use with MS Windows, for example

- Arduino Giga R1 WiFi (STM32 M7/M4) with PC uplink and power over USB hub.

- Giga Display shield (touchscreen) GUI using EEZ Studio.

- Custom shield with Click/mikroBUS interfaces and other custom interfaces used simultaneously with Giga Display shield.

- Boards for sensors, for example high resolution temperature sensor click board with LTC2983.

- Interface for legacy manual switches.

- ribbon to custom power distribution based on automotive high current STM VN* high-side and bridge drivers (for example 20 A) and low current 0.5 A 12-channels (OnSemi NCV7726, H-bridge driver with SPI interface) for 12 – 24 VDC in/out.

Examples of PhotoSound data acquisition products

- ADC256 R1.2 with Artix-7 200T, 4x SPF+ and USB3 interfaces, 233.35 x 160 mm size. R1.3 will be 6U enclosure based for up to 16 ADC’s or 4096-channels per enclosure.

- PhotoSound ARC card, 8x GTHs to 2x QSFP+ / QSFP28 (up to 16.3 Gb/s), PCIe Gen4 x4, DDR4, SI5395 clock. PC-bracket, FPGA heatsink and DDR4 SODIMM-260 (single-rank 72-bit ECC) are not installed. QSFP+ uplinks are user selectable as GTH 16.3 Gb/s or LVDS or clock using programmatically controlled 3:1 20 Gbps switches.

- 16-channel preamplifier, two channels marked red (4.0 x 20.0 mm minimal footprint with 2-sided layout).

- Left: Power distribution board with 600W 24 Vin, 24V 300W heater-out control and 24V to 12V 240W conversion and 12 V control. Right: Arduino Giga shield with IDC ribbon connector for power distribution board control and 2x Click board and 2x mikroBUS-shuttle sockets. Arduino Giga and Giga display is installed to the back of the shield. Click-LTC2983 and ribbon are not installed.

- ASIC1 in 8×8 mm open cavity QFN56 package: top, bottom and open empty package. ASIC16 in 12 x 12 mm open cavity QFN100 package bottom and top.

- Test board with solderless elastomer adapters for ASIC1 (left) and ASIC16 (right).

About PhotoSound Technologies, Inc.

PhotoSound Technologies is a research, development and manufacturing company with a focus on compact multichannel data acquisition systems and imaging technologies. The imaging technologies we develop employ physical processes of photoacoustics, ultrasound, and photonics enabling novel applications and insights in Life Sciences and Clinical research. The employees at PhotoSound are committed to providing every customer with the highest quality products and services, short development timelines, competitive pricing, and first-class customer support. Our company was founded in 2015 and our facilities and offices are located in Houston, TX, USA.